Souliou str. 1 & Pigis Avenue , 151 27 Melissia - Athens

Tel. +30 210 6130 366, 6135 866 , Fax +30 210 6139 787 , E-mail: info@cromemco.gr

Cromemco Hellas SA

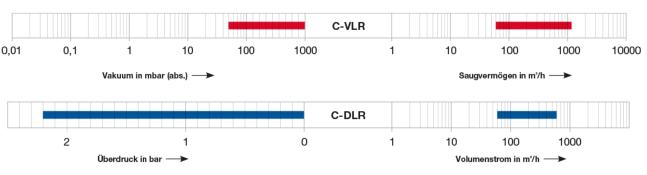

C-Series

Claw

C-Series

Innovative Claw Technology

The C-Series claw pumps and compressors of Elmo Rietschle generate contact-free vacuum or

compressed air efficiently and economically. This is possible because of the principle of internal

compression. The gas is pre-compressed within the compressing chamber and is then discharged.

The use of IE3 motors and optimized air flow geometry decisively reduce your energy consumption

and consequently life cycle costs – as does the flexibility offered by the use of variable speed drives.

External or integrated frequency converters ensure energy-efficient operation that not only meets

legal requirements but also lowers operating costs.

The design with the smallest footprint on the market for claw pumps and compressors also gives easy

access to all components of the machine – easy to service and inspect.

Sound engineering has reduced the noise level by more than 50 % compared to traditional claw

pumps: the VLR 501 for example comes in at only 78 dB(A) for 400 mbar.

Service is due after 20,000 operating hours only – depending on the application. This very long service

interval translates into many hours of uptime with minimum interruption and low service costs.

This leads to an evident energy saving compared to rotary lobe blower designs without internal

compression.

Advantages at a glance

•

Dry, contact-free operation

•

Process safe and reliable

•

No oil in the compression chamber

•

Frequency control available

•

Ideal for Central Vacuum Systems

•

Low sound level

30 years ...

Elmo Rietschle official distributor