30 years ...

Elmo Rietschle official distributor

Cromemco Hellas News

Central Vacuum System by Cromemco and Elmo Rietschle

December 2016

Elmo Rietschle expands its product range for maximum customer benefit

October 2017

The Cromemco team attended at the global distributor conference of Elmo Rietschle in Schopfheim, Germany. At the

meeting we successfully presented our new sophisticated industrial central vacuum system to more than 90 people from

all around the world, It was interesting for everyone…

Read more …

Elmo Rietschle Distribution Conference 2018 in Schopfheim, Germany

June 2018

Cromemco has on November 2019 installed a new Industrie 4.0 , IOT, Sewere Central Vacuum System in the pumproom

at Marina Zea in Piraeus. The system has replaced an older system and controls 2 Elmo Rietschle C-VLR 301 XD Heavy

Duty Vacuum Pumps and 2 sewage pumps. The system is using a Solberg Moisture Separator with an integrated 5 μm

Polyester Filter, type LRS-275-DN100. The fully automated system is communicating via Internet with the operators and

informs about Process Control, Warnings and Alarms. All Process Data are stored every 2 seconds on a cloud server. The

system operators have access on the Cloud Server on the history data. The system is operating 24 hours a day for the full

year and is used to collect sewage from the vessels. The pumproom does not need human actions and has improved the

pumproom environment. Hi energy and maintenance cost saving, brings a rapid return of investment.

Read more …

Sewere Central Vacuum System installed at Marina Zea in Piraeus

November 2019

Cromemco has installed an Industry 4.0 full IOT Vacuum Center dedicated to work with Wood CNC Centers. The system

is Maintance Free. Only an Oil Change is necessary every 10000 hours. The fully automated system is communicating

via Internet with the operators and informs about Process Control, Warnings and Alarms. All Process Data are stored

every 2 seconds on a cloud server. The system operators have access on the Cloud Server on the history data.

Read more …

Central Vacuum System installed at the EXPA’s factory in Paros is supplying

a CNC Wood Processing Center

December 2019

The new Industrial Central Vacuum System Project from Cromemco, is utilizing 4x Elmo Rietschle C-VLR501 Claw Vacuum

Pumps and a sophisticated IOT Automation System, based on Siemens Simatic S7 1500 PLCs and Sinamics G120P VSDs.

The filtration and Air-Oil Separation is done via Solberg LRS-275-DN150 filters. The System will be ready installed at the

end of October 2020. The PLC is also controlling a spohisticated HVAC system for the pumproom. The total energy cost

drop and the strong reduction of the maintenance cost will help to achieve a very quick retun of investment. The system is

utilizing an IOT SCADA application, which informs the operators using a lot of forms, graphs, reports and a flexible

notification system through E-mails or SMS, about all system process values, parameters and alarms. More than 1000 tags

are stored every second into the system SQL database. The monitoring of the system is also possible through any

smartphone, Tablet, Laptop or PC.

Cromemco has developed the automation system with EPLAN pro Panel and the mechanic parts using 3D CAD CAM.

The Digital Transformation is showing on the pictures at the left.

Read more …

2nd Central Vacuum System will be installed at BIC Anoixi

July 2020

`

Cromemco is representing Nash in Greece and Cyprus

July 2023

Cromemco haw started a new cooperation with Nash. Cromemco is representing Nash in Greece and Cyprus.

Nash is building the famous liquide ring pumps, mainly to be used in the chemical industry.

Read more …

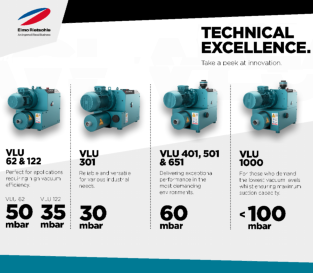

The VLU. The pinnacle of claw vacuum technology has arrived !

April 2024

This patented vacuum pump combines innovation and sustainability to deliver an ultimate vacuum level as low as 30 mbar

(abs.).

The VLU is a genuine alternative to traditional oil lubricated vacuum pumps and with an optimum total cost of ownership it is

the greener solution for many applications.

Welcome to a future with no oil, no air contamination, and no waste. Cutting-edge oil free technology ensuring longevity and

consistent performance.

C-VLU is produced for capacities of 62, 122, 301, 401, 501, 651 και 1000 m3/h.

Copyright 2025, Cromemco Hellas

Souliou 1 & Pigis Avenue

15127 Melissia - Attika

T: 210 6130366, 210 6135866

F: 210 6139787

E: info@cromemco.gr

Cromemco has installed in December 2016 a new sophisticated Industry 4.0 and IOT compliant central vacuum

system, at the Bic facilities in Anoixi, Greece.

The full automated redundant system, not only controls the Elmo Rietschle vacuum pumps, but is also logging

every significant process value, relevant to the vacuum supply and energy consumption at each suction point.

The system is also controlling the ventilation and the cooling system of the pump room and notifies via e-mail

whenever it’s necessary.

The system has been developed to replace 30 standalone oil lubricated vacuum pumps 200 m3/h each. A very

stable operation saves 65% energy through the innovative energy efficiency and is additionally reducing

maintenance costs. The cooling system energy gain is greater than 93%. The five Elmo Rietschle, claw vacuum

pumps C-VLR 1000 operate between 24-60HZ with an ultimate vacuum up to 200 mbar abs. The System is

ready to support one more pump.

The automation is based on the Siemens Simatic PLC S7-1500. Five Siemens Sinamics G120 22 kW Inverters

control the pumps via PID algorithm. The design and the documentation are accomplished with EPLAN Electric

P8. Furthermore, the whole system is documented in 2D and 3D drawings to reduce manufacturing errors and

make troubleshooting easier.

A very sophisticated detailed SCADA System, based on Siemens WinCC Professional, allows operators and

engineers to monitor and control the system. A WEB Server, build by Cromemco, is serving on any computer,

Tablet or Smart Phone, several Web SCADA pages

Elmo Rietschle the German daughter of Gardner Denver is launching an impressive addition to its existing

product range at this year’s HANNOVER MESSE on Stand B60 in Hall 26. A new XD range for heavy duty

applications has been added to the claw, rotary vane and screw technologies and the IV range will be

launched for low ultimate vacuum models for the rotary vane and screw vacuum pumps.

The vacuum and pressure specialists for industrial processes have acquired an excellent reputation in many

decades of successful business dealings with customers around the world from many industries – and they

have seen an ever increasing demand for more complex and diversified solutions. One solution for all needs?

The engineers in Schopfheim and Bad Neustadt believe that details count and that one product for all no

longer satisfies the technical and financial requirements from today’s customers. A change for more

application focused machines is the result of this new approach.

XD is the label on the new heavy duty models for the claw, rotary vane and screw machines which are

primarily intended for humid processes. They feature protective coating, are resilient to dust and dirt carry-

over and are best suited for demanding applications such as extrusion, industrial parts cleaning, meat

processing and packaging. They are available with variable speed drive to keep the energy bill low.

The second novelty by Elmo Rietschle are the XD models for the VC rotary vane and VSI screw vacuum pump

models that can achieve vacuum of 0.1 mbar. They tolerate high inlet gas temperatures and are especially

low noise. The oil change intervals for the rotary vane vacuum pumps are longer than the industry standard.

Lamination of solar panels, heat treatment, oil degasing and freeze drying are typical applications for these

special machines as well as lithium-ion-batteries, load lock chambers and coating.

VC rotary vane and VSI screw vacuum pumps

as IV models

Central Vacuum System Elmo Rietschle with

5x VLR 1000 pumps